| Size |

mm |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

500 |

| R=Q3/Q1 |

|

50 |

80 |

| Q4 |

m3/h |

31,325 |

50 |

78,75 |

78,75 |

125 |

200 |

312,5 |

500 |

787,5 |

1250 |

1250 |

2000 |

3125 |

| Q3 |

m3/h |

25 |

40 |

63 |

63 |

100 |

160 |

250 |

400 |

630 |

1000 |

1000 |

1600 |

2500 |

| Q2 |

m3/h |

0,8 |

0,8 |

1,26 |

1,26 |

2 |

3,2 |

5 |

8 |

12.16 |

20 |

20 |

32 |

50 |

| Q1 |

m3/h |

0,5 |

0,5 |

0, 7875 |

0,7875 |

1,25 |

2 |

3,125 |

5 |

7,875 |

12,5 |

12,5 |

20 |

312,5 |

| Max. Reading |

m3 |

999999.999 |

9999999.99 |

99999999.9 |

| Min. Reading |

m3 |

0,0005 |

0,005 |

0,05 |

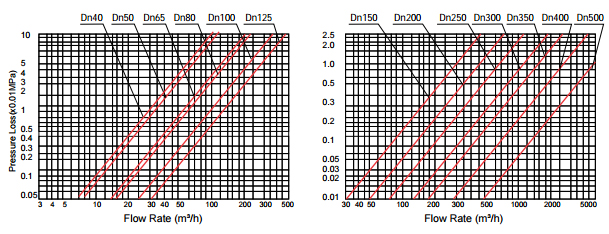

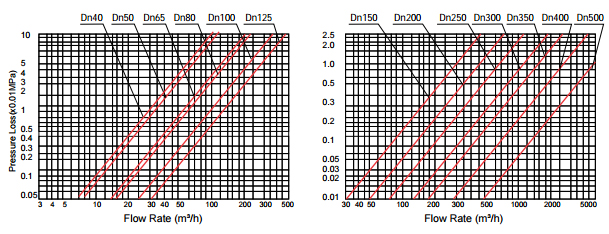

| Pressure Loss |

P |

10 |

16 |

10 |

10 |

10 |

16 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

| Max. Pressure |

MAP |

MAP16 |

| Max. Temperature |

°C |

T30 or T50 |

Pressure Loss Curve

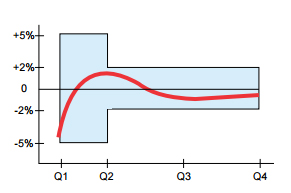

Max. Permission Error:

From Q1 inclusive up to but excluding Q2 is ± 5%;

From Q2 inclusive up to and including Q4 is ± 2%

for T30 and ± 3% for T50;

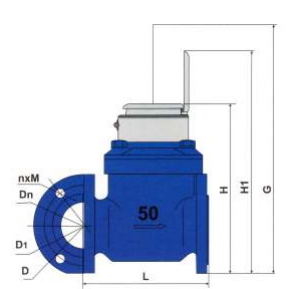

| DN |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

500 |

| L |

260 |

200 |

200 |

225 |

250 |

250 |

300 |

350 |

450 |

500 |

500 |

600 |

800 |

| H |

225 |

252 |

262 |

272 |

282 |

297 |

341 |

371 |

480 |

516 |

560 |

647 |

785 |

| H1 |

303 |

339 |

349 |

359 |

369 |

384 |

428 |

458 |

576 |

603 |

603 |

723 |

838 |

| G |

360 |

400 |

400 |

400 |

400 |

400 |

500 |

500 |

710 |

730 |

730 |

830 |

930 |

| D |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

405 |

460 |

520 |

580 |

715 |

| D1 |

110 |

150 |

145 |

160 |

180 |

210 |

240 |

295 |

355 |

410 |

470 |

525 |

650 |

| n x m |

4 x M16 |

4 x M16 |

4 x M16 |

B x M16 |

B x M16 |

8 x M16 |

12 x M20 |

12 x M20 |

12 x M24 |

12 x M24 |

12 x M24 |

16 x M27 |

20 x M30 |

| DN |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

500 |

| L |

x |

250 |

250 |

200 |

300 |

x |

x |

430 |

x |

x |

x |

500 |

500 |

| L |

x |

270 |

260 |

270 |

360 |

x |

x |

x |

x |

x |

x |

x |

x |

| L |

x |

310 |

x |

300 |

483 |

x |

x |

x |

x |

x |

x |

x |

x |

| L |

x |

x |

x |

413 |

x |

x |

x |

x |

x |

x |

x |

x |

x |

*Different Flange Standard for selecting such as: ISO 7005-2: 1998(E) PN10, ASME B16.1-Class125 working forB16.5-Class 150...

*Different Length of the Body as option

Installation

- The water meter could be install in any position, for non

horizontal positions the flow shall upwards.

- The meter shall be full of water while operation.

- Prior to installation of a meter, the pipeline shall be

thoroughly flushed.

- Straight pipe section of the same diameter D as the meter,

having length of 10D and 5D shall be installed upstream and

downstream of the meter respectively.